Customer Stories

Develops, manufactures, and sells medical equipment

Mita Rika Kogyo Co., Ltd. – a small family business based in Osaka – develops, manufactures, and sells medical, scientific, and pharmaceutical equipment that utilizes cleaning and sterilization technology. Since the company’s inception more than 70 years ago, two generations of the founder’s family have steered the business through its long history.

The decision to adopt Kintone was made around the same time that Mr. Jun Chigusa – Senior Managing Director and the future third-generation successor to the family business – joined the company. We spoke with Mr. Chigusa to find out more about why the company ended up deploying Kintone as a cross-departmental information platform for its Sales, Maintenance, and Manufacturing teams.

Before deploying Kintone:

Management of customer information was fragmented across multiple channels, including Excel spreadsheets, emails, and verbal communication. No standardized record of customer interactions, forcing members to spend up to 1.5 hours getting ready for sales calls.

After deploying Kintone:

All customer-related information, including past interactions, is registered on Kintone. No need to check multiple channels to find the required data. Members can prepare for sales calls in 5 minutes.

Founded in 1949, Mita Rika Kogyo Co., Ltd. provides hospitals with medical, scientific, and pharmaceutical equipment developed with its cleaning and sterilization technology and creativity cultivated over many years. It specializes in providing a range of solutions and services that facilitate the preparation of baby formula – a breast milk substitute based on powdered milk that is suitable for feeding to infants. Some of the solutions and services offered include bottle feeding room designs, cleaning, sterilization, baby formula water production, bottle filling, disinfection, refrigeration, sales of other consumables for use with these products, and after-sales maintenance. As a leading provider of baby formula-related services, Mita Rika Kogyo provides a vital contribution to pediatric nutrition in Japan.

Although the company did have a core IT system for sales management and other tasks, they relied on emails and Excel spreadsheets to manage customer data, sales activity logs, sales calls, and to track previous repairs and repairs in progress. This created people-dependent information silos that disrupted information sharing.

“Back when I joined the company as the designated successor to the business, customer data was scattered across different departments, with no centralized management. My very first assignment was in the Sales team. The only handover documentation I received was a single A3 sheet of paper – I had to shadow my senior colleagues when they met with customers and take notes to familiarize myself with our customer accounts. There was so much I had to learn about the business, our customers and the equipment we sell them, and yet we didn’t have the proper documentation to onboard new colleagues. I felt that this onboarding approach was only making the process of getting new people up to speed harder,” Mr. Chigusa recalls.

This situation created other problems as well. For example, when the company President issued instructions to boost the number of sales visits, plans developed by the Sales Division were frustrated by the lack of visibility into the actual number of sales visits, since that data was only known to the sales representatives working on the specific accounts. The same lack of visibility became an issue in internal sales meetings as well and made it difficult for the team to move through the PDCA cycle.

“Quite frankly, despite being the designated successor, I didn’t feel I could take over the business unless this situation changed. Even with the really talented and kind people we have working here, that kind of work environment was just really tough for newcomers to adapt to. That’s when I realized we needed a system that would allow us to share and track customer-related information – such as sales history and the status of repair tasks – across the entire organization,” Mr. Chigusa remarks. That is what led him, a mere three months after joining the company, to make the decision to establish a work platform that would be easy to use for everyone.

Initially, Mr. Chigusa considered adopting some kind of SFA tool as an aid for the Sales team. However, he ultimately decided against it. He found that the business needed a platform for sharing customer-centric data. This platform could not be confined to the equipment sales team – it should also aid employees working in consumables sales and equipment repair.

Mr. Chigusa elaborates, “If you are a member of the repair team, you need a Master Equipment Delivery database to track the history and progress of your repair tasks. But if you work in the sales of consumables area, you need an environment that lets you analyze past deliveries to identify the best timing for your next sales pitch to the same customer. There was no point in working on making sales operations more efficient in isolation – we needed a highly versatile tool that could be tailored to suit the realities of our business.”

That was when Mr. Chigusa turned his attention to Kintone, which he had experience using from his previous job:

“Initially I had considered Microsoft Access and Salesforce, but the level of technical knowledge needed to master those tools made them too complicated for a Liberal Arts major like me. But with Kintone, I knew that all I needed to do to create a new application was to drag and drop on the screen. And with the wealth of information available on social media and YouTube, I sensed that Kintone was the right service to help us create applications on our own.”

Mr. Chigusa shares how during the initial deployment of Kintone, he attempted to convince the sales representatives to switch to using a Kintone app instead of emails to submit their daily reports. This turned out to be difficult to put into practice:

“Our employees struggled to transition away from the old reporting process, a struggle I could sympathize with. But I was confident that in time the data we accumulated by using Kintone would become an asset that would prove crucial to the future of the business.” Although Mr. Chigusa was unable to get the system off the ground in the first year after the initial deployment, his resolve was renewed when he saw how another app made by clerical staff in the Repair Sales Department started gaining traction. He also found that reframing his request to submit daily reports in Kintone into a rule gradually helped expand usage of the app throughout the organization.

According to Mr. Chigusa, Kintone has helped the company realize significant efficiency gains in the company’s front-line sales operations. In the past, every sales call with a customer required the sales representative to gather and collate every piece of data on that customer and their history with the company. This process took around 90 minutes, per call. Now, however, that same sales representative needs less than five minutes to get ready for a sales call, since all they need to do is look up the customer data registered in Kintone.

Using Kintone to establish a work platform also helped the company to dramatically optimize its internal work processes. Past workflows would force employees to waste time and effort on entering the same information again and again. In contrast, Kintone allowed data entered in one step of the process to be reused in subsequent steps, ensuring that employees only needed to enter new data once. Mr. Chigusa elaborates on the positive changes enabled by Kintone in this area:

“For example, for repair work, we used to enter the same information many times across multiple Excel sheets, including separate repair schedule management and repair history sheets. Now we don't have to do that anymore, which has allowed us to reduce both our overhead and the number of data entry errors."

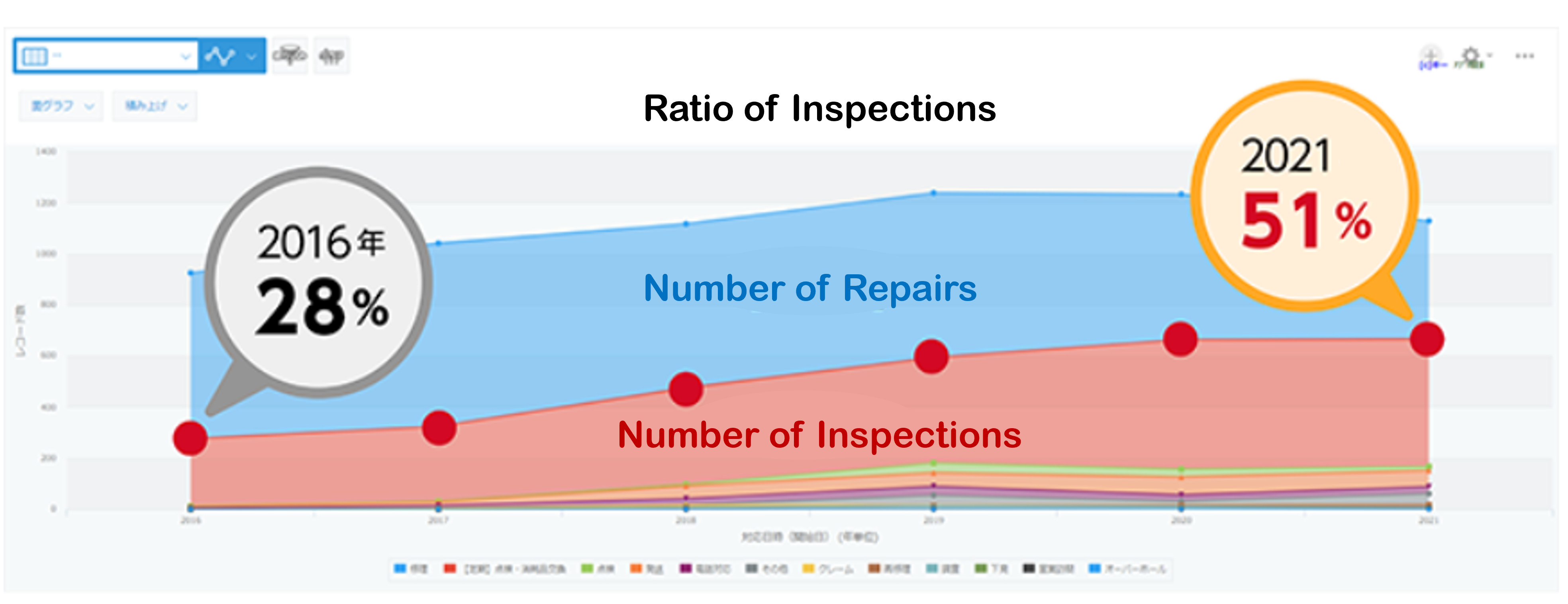

The benefits of deploying Kintone to streamline information management are also appearing in the company’s sales figures. In the past, the number of repairs performed was higher than the number of inspections of delivered equipment, but now that the company has a CRM solution built around customer data, team members gain full visibility into the status of repair and inspection tasks associated with every customer. Mr. Chigusa is clear on how much easier Kintone has made it to advise customers of upcoming inspection due dates at the right time:

“By making a list of customers who had repairs done a year ago, it has become easier to send out inspection notices, and we now have a system that allows us to advise customers that equipment is due for inspection and to take action in advance, rather than waiting until a breakdown occurs. Previously a lot of customers waited until a device broke down before they got it repaired. However, as a result of inspection due notices being sent out with Kintone, the percentage of customers getting their equipment inspected is now above 50%. That percentage was only 28% five years ago. This growth in the equipment inspection rate has given us a more stable revenue stream and made it possible to prevent breakdowns before they occur. The end result is less trouble for customers, and more predictability for the repair team – they can now plan ahead instead of scrambling to respond to unexpected problems on an ad-hoc basis."

This single improvement – giving the team room to plan their activities ahead – has also contributed to big improvements in the way the employees work, including a big reduction in overtime work.

Currently, all 30 or so employees that use computers have been given Kintone accounts, creating an environment where information is equally available to everyone.

“We used to be a very top-down organization with authority concentrated at the top. Things were not very transparent, since all cross-departmental communication had to go through the President. Today however, employees are able to find the information they need, even if that data comes from other departments in the organization,” Mr. Chigusa remarks.

Reflecting the company’s strong focus on user-friendliness, they have added significant customizations to their version of the Kintone Portal start page.

A tab-based display makes it easy to navigate to other necessary portals, such as apps, calendars, dashboards, spaces and manuals. The design of the system, including the button layout and color coding, is customized to provide immediate access to the necessary apps, and new improvements are constantly in the pipeline. The company is constantly striving to make the system as user-friendly as possible.

“We need to make the platform as easy to understand as possible to get people to switch from Excel and paper to Kintone. We are especially focused on improving usability on a day-to-day basis, for example, by immediately correcting issues that diminish the user experience," explains Mr. Chigusa.

Many other Kintone apps are used by the front-line sales members. A Customer Minutes App logs visits to hospitals, including information about the time of the visit, the participants, and what was discussed during the visit. The Lead Progress App allows users to see information about individual leads on one screen, providing visibility on metrics like the likelihood of closing the lead and the number of recorded daily reports. These two apps are linked using a Kintone integration service that aggregates minutes from the Customer Minutes App and displays them in the Lead Progress App. The Delivery Master App gives insight into customer-centric data for client hospitals, including information about relevant departments and contact persons, as well as data on the usage of baby bottles. It also provides a visual snapshot of completed equipment deliveries, pending consumables, and ongoing repair tasks.

“Each department can enter their own information into the app, and it will all be reflected in the Delivery Master App. As long as we check the data in the Delivery Master before visiting a customer, we can immediately analyze the operational status of the equipment and identify the right time to pitch new consumables," Mr. Chigusa explains.

In many cases, new apps are created in response to requests from the front-line staff and prove highly useful for business operations. For example, the Measuring Instrument Registration Ledger App, which keeps track of the calibration status of the various measuring instruments required for product development, was created in response to requests from the people in the product development team. In addition, the number of members who can create apps is increasing. One example of this is the Measuring Instrument Take-Out App, which was created by a new member of the company who took the initiative, and it is used when members take measuring instruments out of the office. Other apps, such as the Anything Goes Message Board App, which helps stimulate communication, have proven instrumental in creating opportunities for greater collaboration between geographically separated offices. There is also a Complaint Report App for managing inquiries and questions, and a Positive Comments App for sharing positive feedback and reviews from customers.

In closing, Mr. Chigusa shares his ambitions for the company’s future use of Kintone, saying “Our current processes represent the culmination of a refinement process driven by our President for 20 years, and our Chairman for 50 years before that. With my measly four years’ experience in the business, there’s no way I will be able to inherit all of that expertise. My goal is to take the know-how and roles currently held by the President and open them up to as many team members as possible, so that we can transform our organization into a smoothly-functioning soccer team where each and every employee is a proactive, collaborative player with their eye on the ball. I see Kintone as a tool that will grow along with us, and that allows us to retain and leverage the information we need to accomplish that goal. I have even greater expectations for what we can achieve together with Kintone moving forward.”

Kintone Product Introduction Video